Generic ERP Systems When you first start exploring the world of ERP (enterprise resource planning) software, it’s easy to become overwhelmed by all of the options. There are several types of ERP systems, each serving a distinct function. While a basic ERP system is absolutely an option, your company may profit more from specialist software. This is especially true for manufacturers.

Continue reading to discover more about the differences between ordinary ERP software and specialist industrial ERP solutions.

What is Generic ERP?

Generic ERP handles the core tasks of a business. These are entirely integrated components that function in tandem to manage business activities efficiently. It may be used as-is or adapted to fit more particular requirements. With generic ERP, the workflow is revised in real-time, ensuring that everyone has up-to-date information at their fingertips. Furthermore, it delivers dashboards that display vital information and assist managers in making wiser and quicker choices by allowing them to quickly and easily access deep analytical data.

What is Manufacturing ERP?

Manufacturing ERP software is designed mainly for the functions of a manufacturing company. It has modules that manage both the front and back ends of the company and are wholly integrated to operate together to create an end-to-end solution. It is intended to assist producers in gaining control and overcoming the obstacles that the manufacturing sector faces.

Manufacturing ERP Vs. Generic ERP

| Areas of Comparison

Functionality Customization Modules Maintenance and Development Vendor Knowledge |

Manufacturing ERP

It is intended to provide an extensive capability for specialized production requirements, such as integrating with shop floor machinery and powerful stock and quality assurance capabilities. Because it is developed for manufacturing organizations, it is less likely to require customization, therefore it is more likely to have the essential capabilities. Manages both general business and production processes. Your provider, who should have extensive industry knowledge, will manage and improve your manufacturing ERP. Manufacturing ERP vendors should understand the challenges of the manufacturing industry faces, and how to counteract them. |

Generic ERP

It is intended to meet fundamental business requirements and is not industry-specific. This is determined by the nature of the business. If how it functions out of the box is sufficient, then customization is not required. Nevertheless, if more functionality is required, some customization is required. Handles fundamental business tasks. If you purchase a workplace automation system from a third-party seller, you will need to purchase additional software. When you require maintenance and upgrades to guarantee that two or more programs continue to function together, add-ons might become an issue. And, because they have distinct interfaces, this can become costly and complex for users. Generic ERP Vendors should understand basic business functions, and if more specific capabilities are required, outside consultants should be engaged. |

Which ERP is Right for You?

To determine which is best for your company, you must first assess its requirements. The methods below will assist you in deciding which ERP system is best for your business.

- Study your company’s operations and the obstacles you must overcome.

- Determine which software skills will be required.

- Conduct some research on several systems to determine if their functionality suits the demands of your business as you have outlined them.

- When deciding on a system, make careful to read the reviews.

- Avoid doing much tinkering.

- Speak with the suppliers to answer any queries you have about functioning or other issues.

Do you still have concerns regarding distinguishing between a manufacturing ERP and conventional options? Connected IT Consulting will be delighted to supply you with further information if this is the case. Our consulting organization is your one-stop-shop for ERP solutions.

We have the experience and resources to assist you in locating the finest ERP for manufacturing for your company. You may get started by contacting our team of specialists.

Related Links

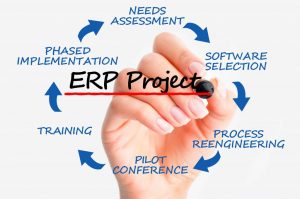

ERP Project Management

Business Process mapping

Small Business ERP

ERP Consulting